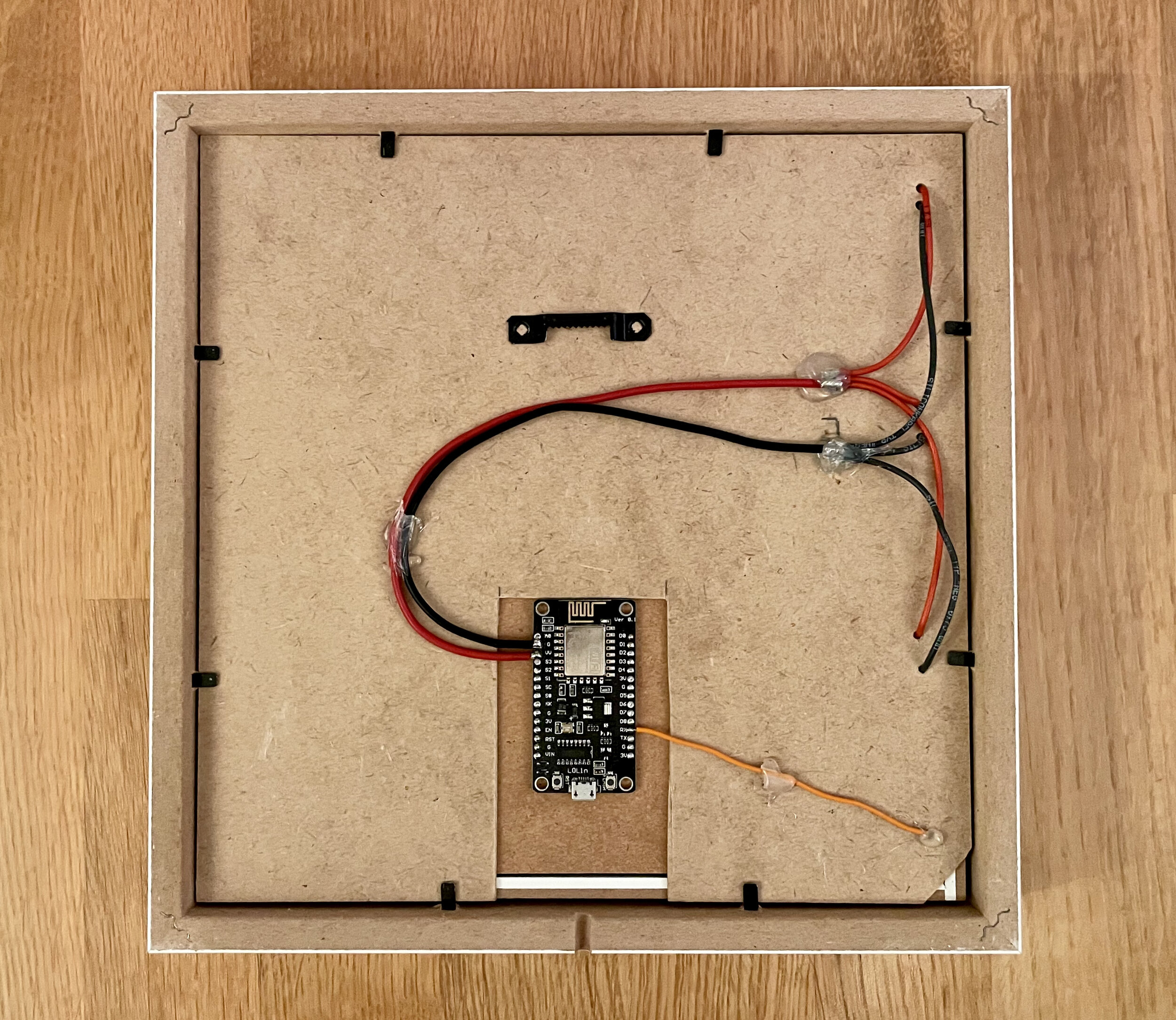

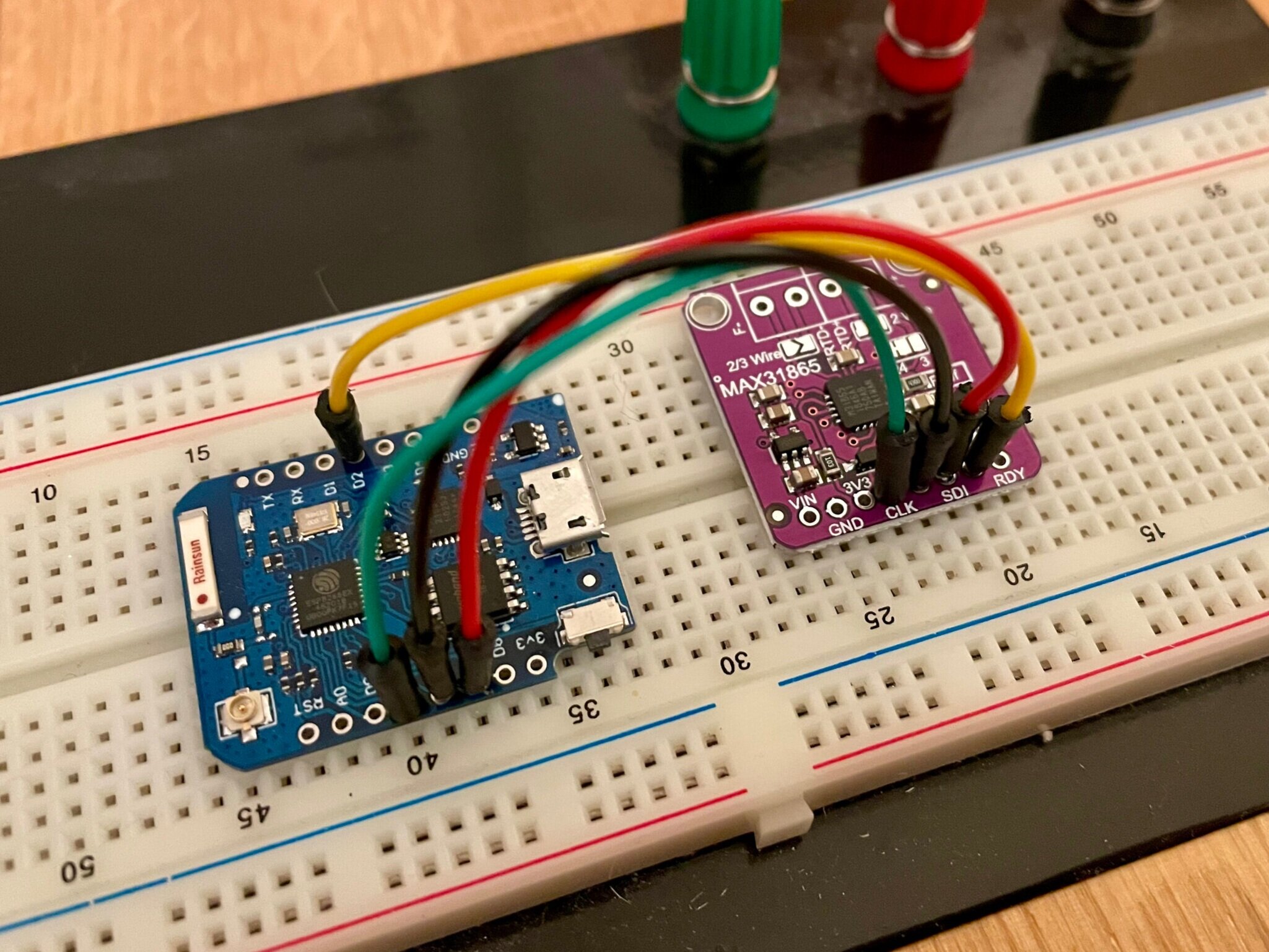

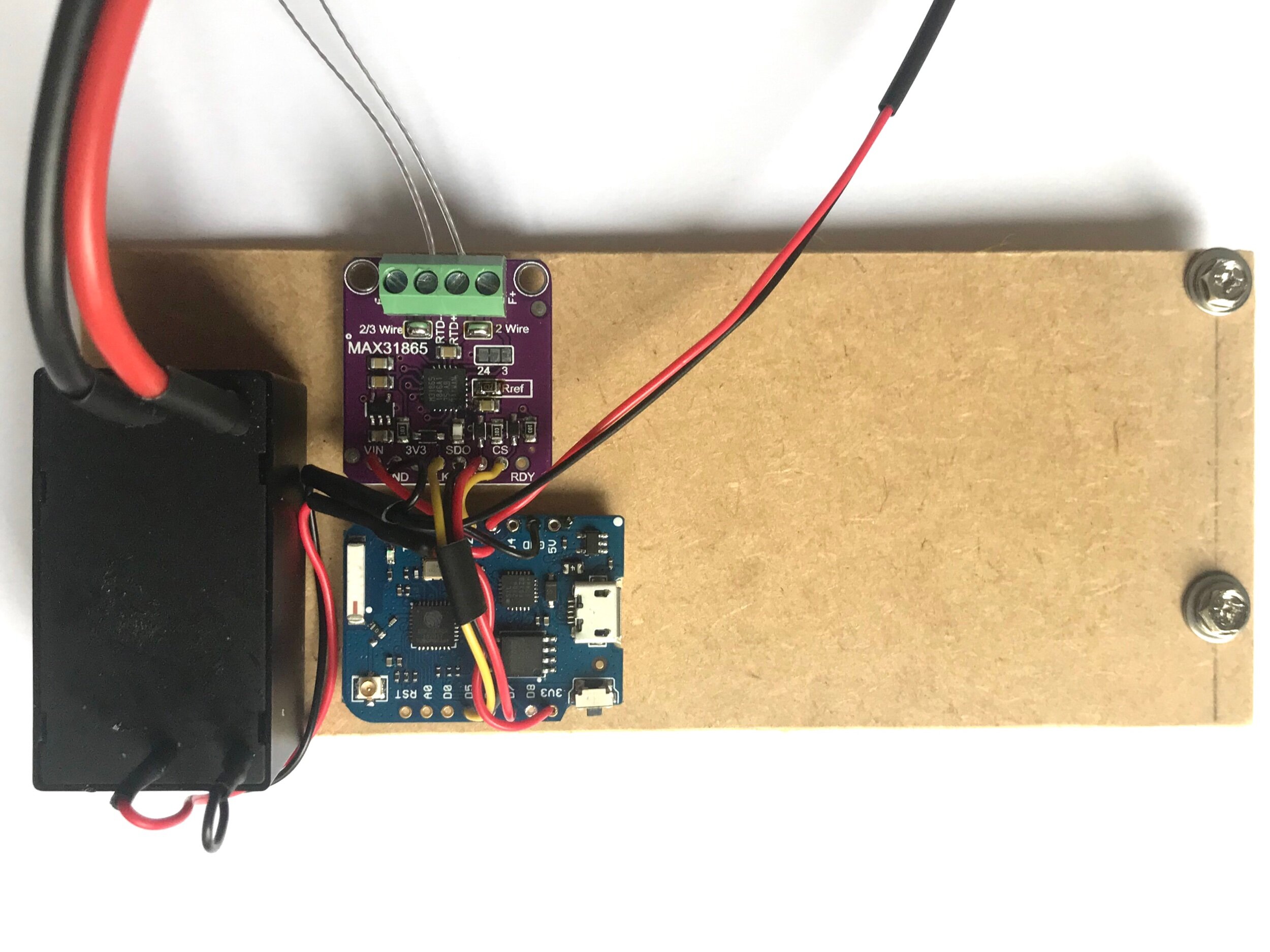

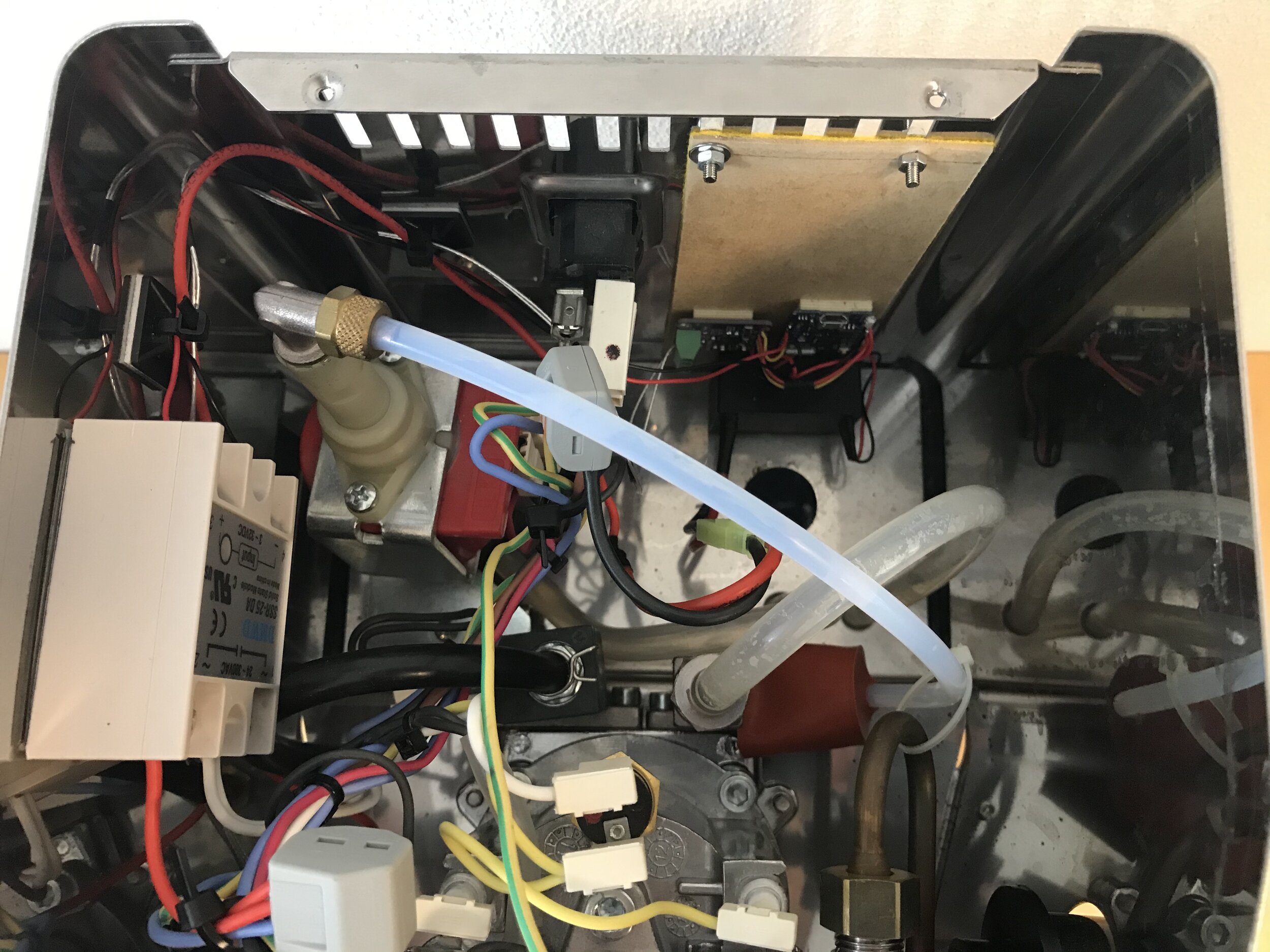

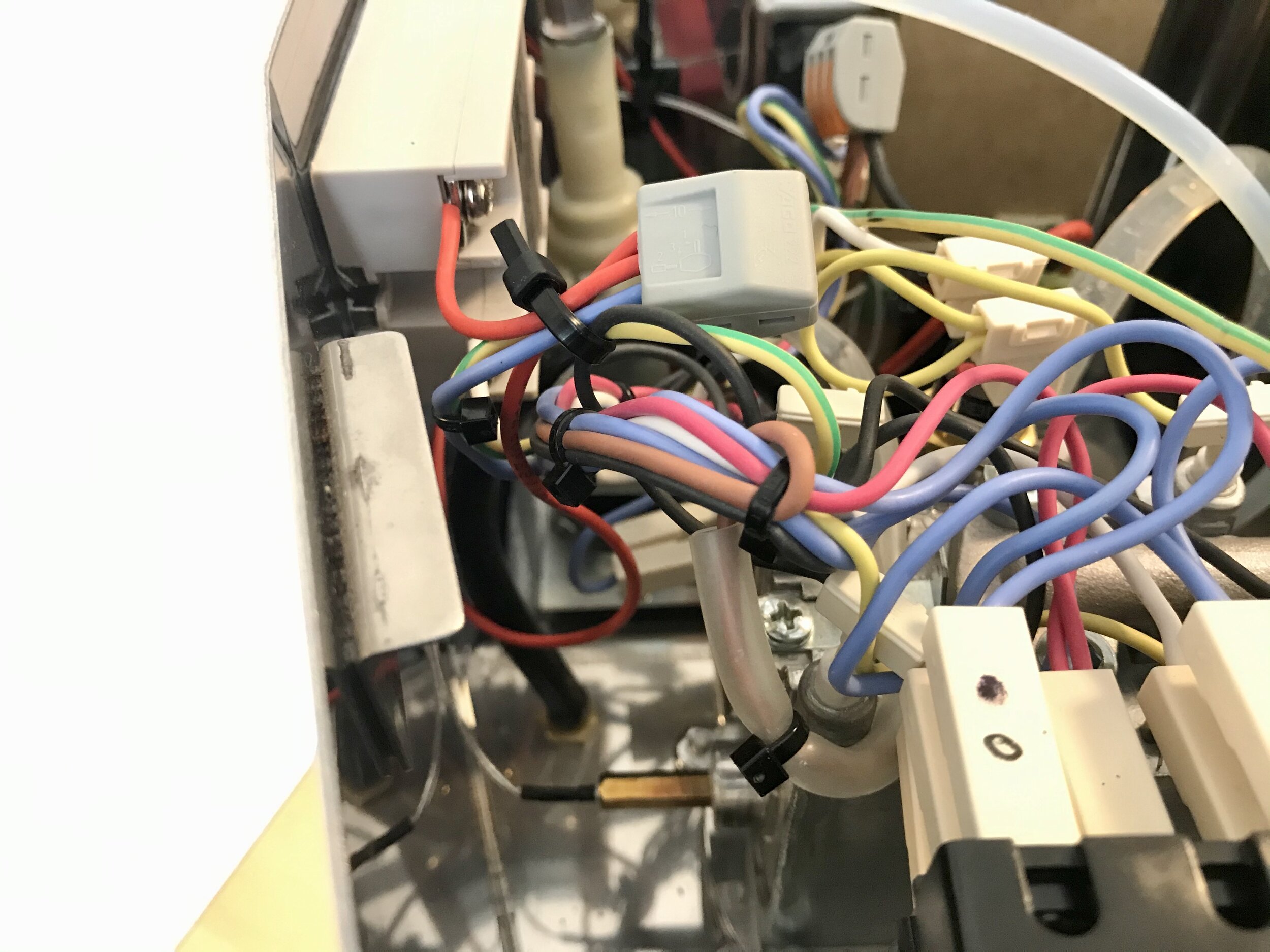

The controller part could be implemented using one of many different microcontrollers available. To keep the complexity of the project low I wanted to use sth. Arduino compatible yet powerful. In other projects the ESP8266 has always been a good friend, so it should cope with this challenge easily. I especially like the WEMOS D1 mini pro board for development and even static use, as it is very compact, can be directly programmed, has enough CPU power, flash and IO and is pretty cheap (around 3€ a piece at AliExpress). It also offers the possibility to connect an external antenna. At this moment I want to have this option as a backup, because I intend to use WiFi functionality of the ESP8266, what is very likely a very bad idea. Putting the chip inside a massive stainless steel case may impact wifi performance, that’s when an external antenna should come in handy.

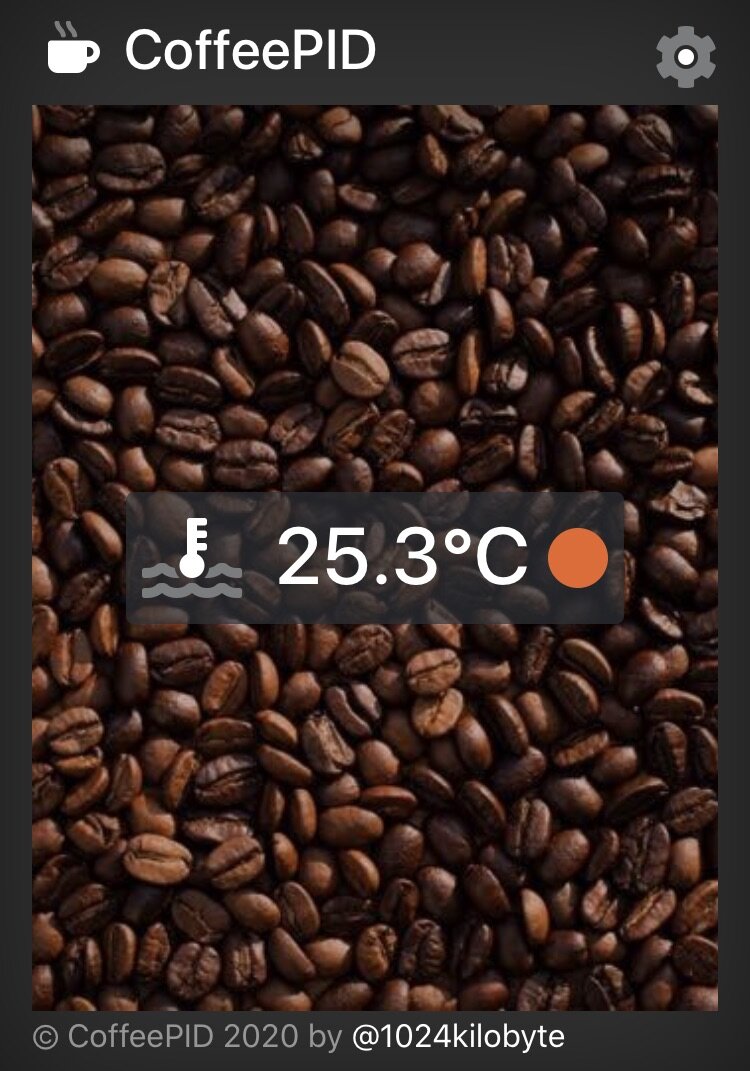

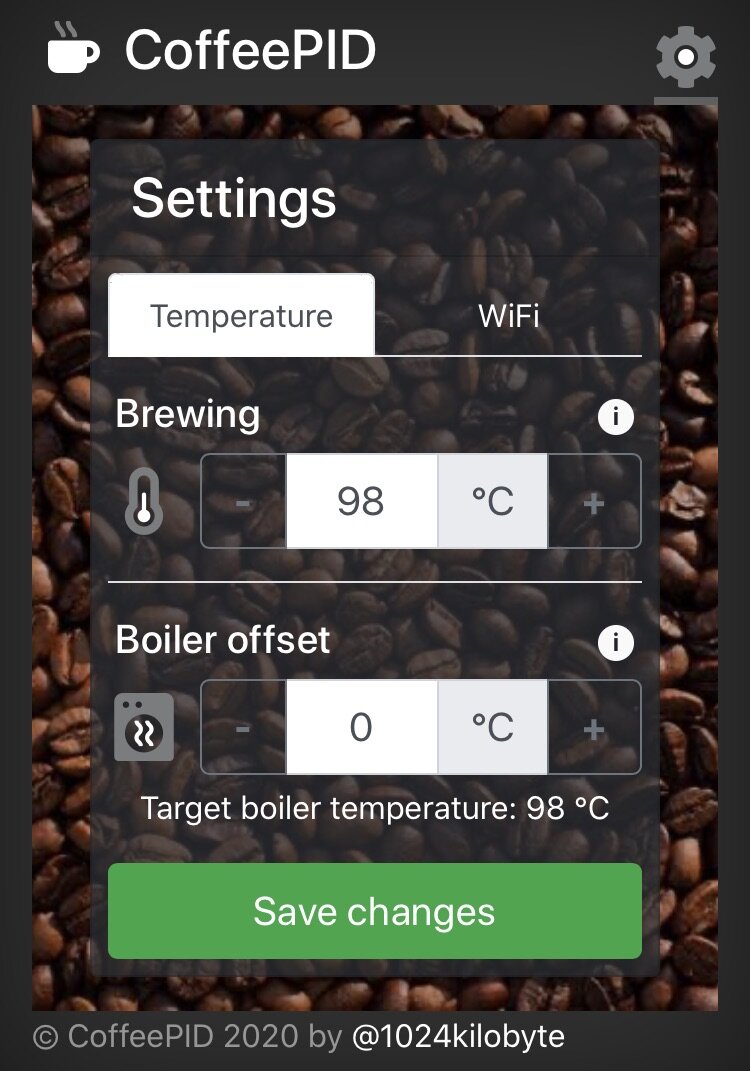

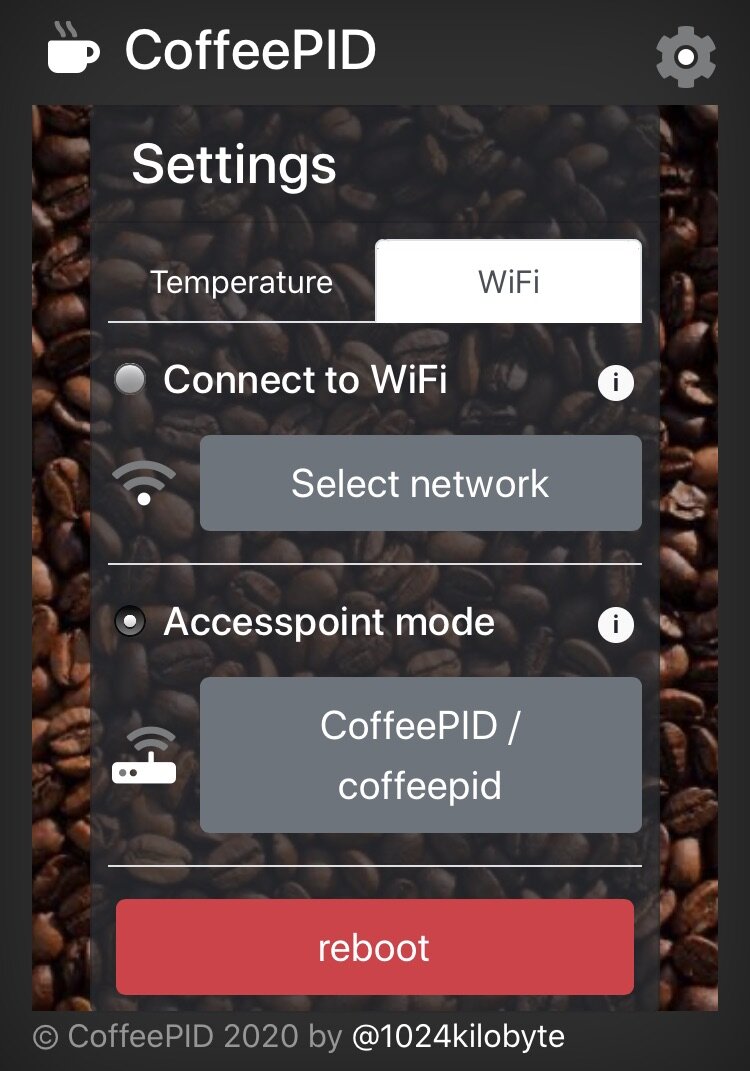

The next decision was on how to set and display the temperature: buttons and a display? But then how about the original look of the machine? I had some doubts about it, but I decided to go with a web interface served via the ESP. It is plenty quick, can act as an access point or as a wifi client, and with some love to the details it should be very easy to use.

As of now, I already have a lot of code running, but I will come back to this later and first complete the list of hardware choices.

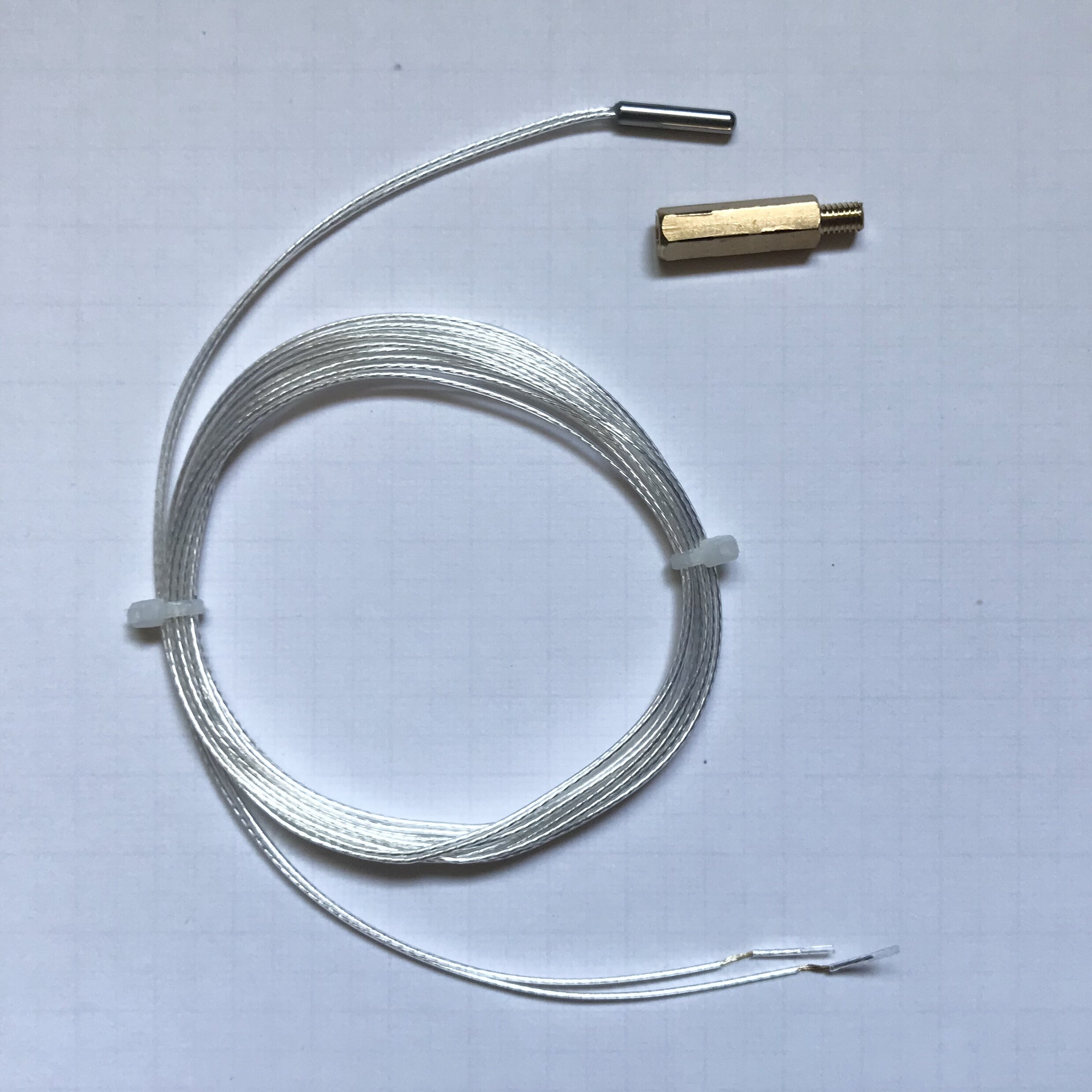

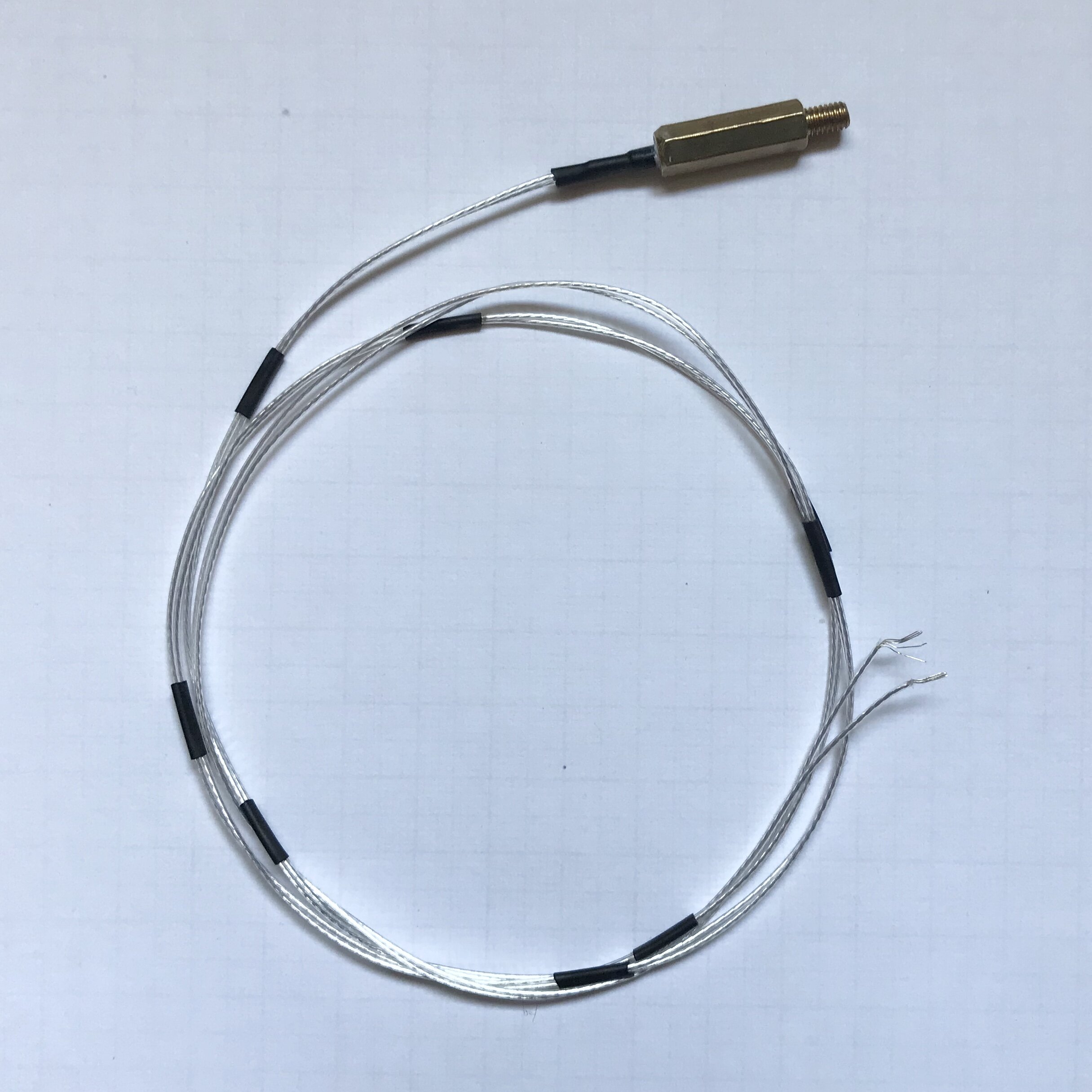

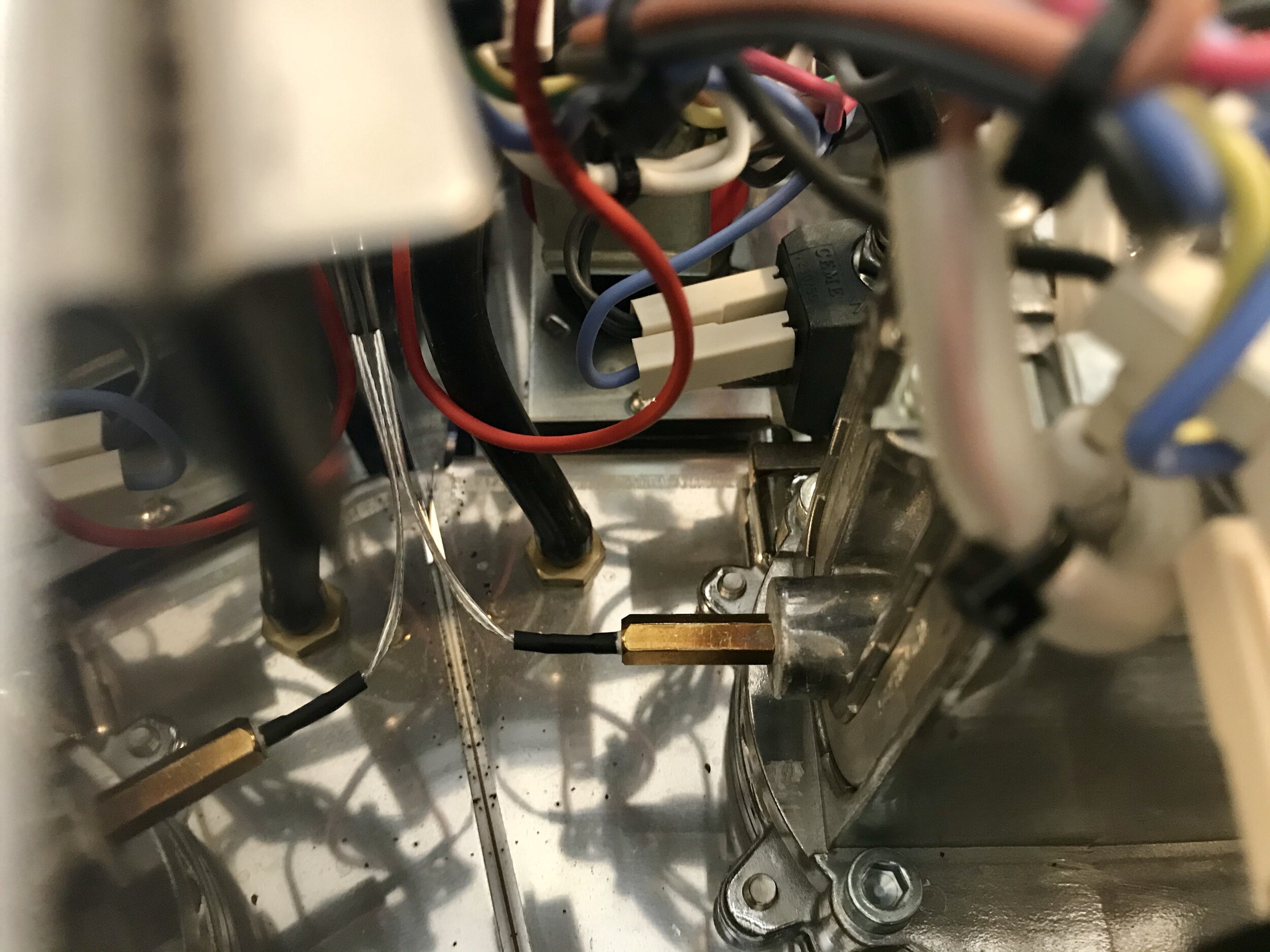

Next up: measuring the temperature. This was actually pretty hard, as I wanted it to be really precise. And as I looked around I was intrigued by the idea to have a simple replacement component for the original thermostat, which has an M4 thread. And thanks to the 3D printer world there are a lot of M4 threaded type K thermocouples out there. Unfortunately they don’t really fall in the “precise” category regarding measuring accuracy. An error of at least ±2 °C is not acceptable if you aim at .1 precision for an optimal result. There are other and better thermocouple types, but they are in bad supply and not M4 thread compatible, so I started all over. If I had started with a simple google search on “measure temperature esp8266“ I would have learned very quickly that the most accurate (and also easy and cheap) solution would be a PT100 or PT1000 thermo element. So I finally came to the MAX31865 controller and a PT1000 1/3Din (class AA) element. It is very important to choose an element with small error ratings, I also recommend small (short) elements, as they are easier to integrate. In this case the best I could find was class AA (3mm x 15mm), translating into the following error-formula:

E = 0.1 °C + 0.0017 | t | °C

So for our preferred working range around 100 °C the maximum measurement error is 0.1 °C + 0.0017 * 100 °C = 0,27 °C. As this is the max error rating, we can generally assume that the error will be much smaller in reality, especially as we don’t use the thermo element in extreme temperature ranges (mine has a measurement range of -40 °C to 400 °C). An error of around a fourth of a degree in measuring the boiler temperature actually sounds really great to me.

If you want some more details on the type k thermocouple vs. RTD (PT100 / PT1000) question, you should check this comparison.

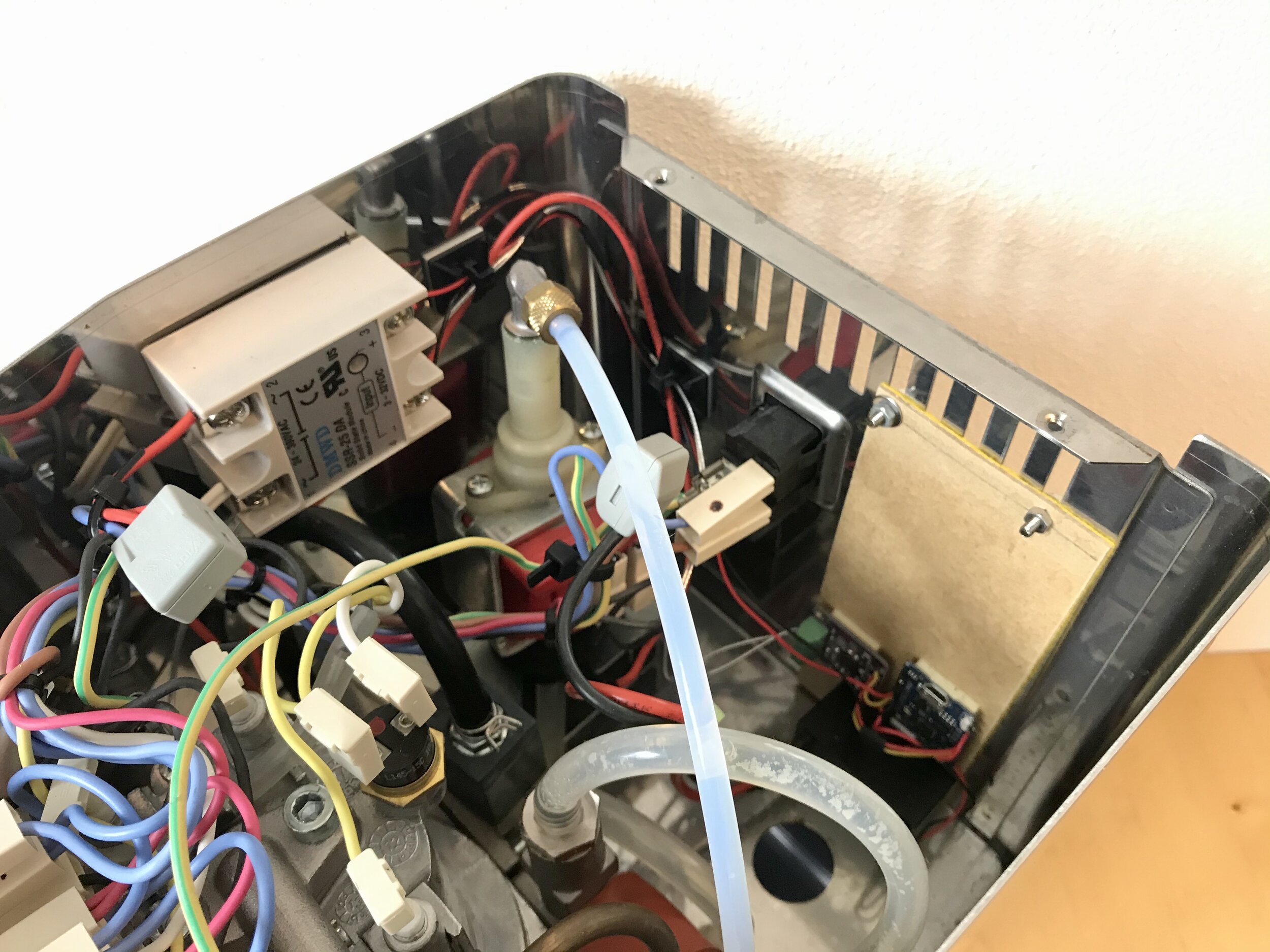

The last two components where finally pretty easy to find. Still missing are the solid state relay to control the heating and the power supply for the microcontroller. The relay has to switch 230V AC just above 5.5 Ampere, as the heater draws a lot of power. So I needed an AC solid state relay that could be switched with an 3,3V input and have a currency rating of at least 10A (better save than sorry here). I finally chose the SSR-25DA (25A AC); yes, the 10A version may also suffice, but if you own the 110V-version of this machine, you would exceed the 10A heating current. Also it is not advised to use these “cheap” SSRs close to their rated limit. And as both versions (10A vs. 25A) are around the same price and size, the choice was simple.

And lastly, an almost boring component, a simple 230V to 3,3V power brick, to power the electronics. In this case I went for a small Meanwell 8.2W print-type power supply (IRM-10-3.3). There are a lot of different models and I expect the actual power drain to less than 1W, so we are again clearly on the safe side.

So finally, all parts ordered……

And I think this is already a good introduction to the project and components I plan to use. In the next posts I will explain the other aspects of this project like the software, website and build in more detail. I hope you enjoyed reading.

P.S.:

As mentioned there are many projects like this out there, this is just my opinionated approach. I want to give you some links to sources that are related and partially inspired me to this project:

OTHER PARTS OF THIS SERIES: